The Unipetrol refining and petrochemical group is an important part of Czech industry. It is the only crude oil processor in the Czech Republic, one of the most important producers of plastics, and the owner of the largest network of gas stations in the country. It is also a major player in refining and petrochemical production in the Central and Eastern European region.

Due to the high fire loads in the petrochemical industry, it is of utmost importance for active, defensive fire protection to have an industrial firefighting vehicle, which is characterized by its versatility in extinguishing agents, as well as the corresponding extinguishing agent volumes or the associated output quantities and, above all, in the operational safety for all types of fire fighting operations, which can extend over many hours / days under maximum load.

To meet these requirements, Rosenbauer configured a fire fighting vehicle for the customer precisely according to the customer’s criteria, which on the one hand consists of internationally proven components manufactured in large numbers, and on the other is tailored precisely to the customer’s needs and requirements.

In this case, the customer specifically required that the piercing tool of the boom be able to penetrate the outer skin of an existing production hall. In turn, we asked for a test piece to be sent to us, whereupon the customer sent us several panels of this hall facade. In the next step, appropriate tests were carried out at the Rosenbauer test site and documented on film for the customer.

Piercing tool of the boom penetrates the outer skin of the production hall

The industrial firefighting vehicle is built on a MAN TGS 41.500 8×4 EURO 6 chassis. When designing/selecting the power take-off and the cardan shaft and their routing, we – in close coordination with the chassis manufacturer – paid particular attention to the continuous load and smooth running of the pump drive train at the customer’s request.

Due to the correspondingly high drive power, the centrifugal firefighting pump achieves a delivery rate of approx. 7,500 l/min at 16 bar in tank suction operation, in order to supply the water turret accordingly – especially for the turret on the HRET (High-Reach-Extended-Turret) at a height of approx. 20 m, a correspondingly high pump output pressure is required in order to achieve not only the required output rate of up to 6,000 l/min, but also a corresponding throw range of approx. 90 m.

In feed-in mode via the local, correspondingly powerful hydrant network, delivery rates of up to 10,000 l/min at 16 bar can be achieved.

The foam proportioning system used is a pump premixing system that has been tried and tested thousands of times and can mix the foam compound continuously between 1-8%. This proportioning system can draw the foam compound from the foam compound tank or directly from an IBC container.

In addition to an RM15C water turret on the front bumper for pump & roll operation, the vehicle has an RM65C on the rear box as well as a 20 m high HRET with an RM65C ChemCore nozzle.

Thus, with this turret at the tip of the HRET, water, foam, as well as foam with powder can be discharged. The foam forms a “hose” through the O-stream nozzle of the turret, in the center of which the powder can also be thrown up to a distance of 90 m. This offers is a highly efficient extinguishing medium, which extinguishes very quickly due to the powder (knock-down effect) and also maintains this extinguishing success sustainably by covering and cooling due to the foam.

The two roof turrets are radio-controlled and equipped with video and thermal imaging cameras on the HRET to provide the operator with appropriate targeting accuracy. The vehicle can carry 8,000 l of water, 4,000 l of foam compound and 1,000 kg of powder as extinguishing agents.

The body of this vehicle was built using the CBS (Customized Body System) design, which has proven itself hundreds of times over and is now being continued in the successor series MT (Modular Technology) with corresponding new features.

By modularly combining various body module and extinguishing components that have been tried and tested countless times internationally, Rosenbauer can implement the individual solution for industrial firefighting in batch size 1 with the quality standard at automotive level in the shortest possible time and with a high degree of cost-effectiveness.

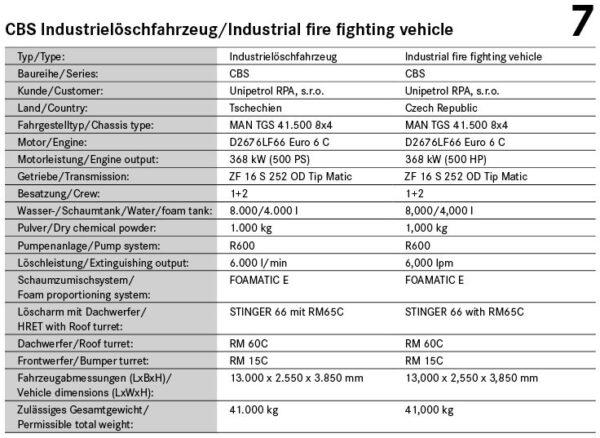

Technical data

This vehicle is now the third to be placed in the petrochemical industry in Central Europe in a relatively short period of time and in a very similar configuration. One of them is located at SYNTHOS Kralupy a.s. in the Czech Republic and another at its parent company SYNTHOS S.A. Oświęcim in Poland.

This vehicle was built using the CBS (Customized Body System) design. The successor series MT (Modular Technology) was presented in October 2020, which enables individualized vehicle solutions for both industrial and municipal areas of application through the modular assembly of various components.

Leave A Comment