Every year in the summer months, forest fires across Europe feature in the coverage of various media. From Germany to Italy, from Spain to Greece, climate change is not only making vegetation fires more frequent and larger, but also increasing the risk period from spring to autumn. Besides all the new modern possibilities for detection, early recognition, and situation reconnaissance by means of satellite-assisted systems and drones, robust and maneuverable vehicles are still an indispensable means of fighting wildland fires.

What makes these special forest fire fighting trucks so special and what must they be able to do?

In a nutshell, the most important thing is the comprehensive protection of the crew. Added to this are off-road capability, robustness, maneuverability and, of course, the ability to fight fire. Let’s take a detailed look at these features using the example of the FFFT3500/100 forest firefighting tanker presented in February 2021.

With regard to the protective equipment for the vehicle crew, a distinction must be made between passive and active systems. In addition to a ROPS (Roll Over Protection System) integrated in the driver’s cab – i.e., a roll cage – the passive equipment in this vehicle also includes separate heat protection insulation for compressed air and electrical lines, which ensure that the vehicle functions even when exposed to heat. In addition to this, special heat protection blankets can be installed in the driver’s cab on the windows, which can be rolled down if necessary and protect the crew from the heat radiation of the fire if the fire gets too close to the vehicle.

In the case of forest fires, it is highly likely that the fire will quickly change direction and come close to the vehicles or even trap the firefighting crews due to the heat and the resulting winds. That is why active protection equipment is even more important in these situations in order to help the crew escape or get out of the fire. Here, the self-protection system is definitely the most important item of equipment. The system includes spray nozzles for the tires and underbody and for the driver’s cab. These nozzles are fed via a 500-liter protected segment of the water tank, so that even after the fire fighting water has been discharged, there is still sufficient reserve for a safe escape in an extreme emergency. The water is pumped either via the centrifugal firefighting pump or via a separate electrically driven pump, so there is also redundancy here if one system should fail.

An additional optionally available active safety feature for the crew of forest fire fighting vehicles is a breathing air supply system. If the fire is already so close to the vehicle that the smoke is starting to penetrate into the driver’s cab, this system offers the possibility of ensuring a supply of fresh breathing air for the crew by means of a respirator mask, which is held above the seats as in an aircraft. Breathing air cylinders installed centrally in the driver’s cab usually serve as the source.

Another active safety feature is that of the Rosenbauer DWD driver warning system, which increases driving safety off-road and warns if the vehicle is in danger of tipping over. Here, sensors permanently measure the vehicle inclination, as well as the axial transverse and longitudinal forces. When approaching a critical area, the driver is warned by visual and acoustic signals.

Compared to all this safety equipment, the firefighting gear seems almost conventional by comparison. In addition to the combined normal/high-pressure pump NH25 with a capacity of 2,000 l/min at 10 bar (FPN 10-2000) as well as 400 l/min at 40 bar (FPH 40-250), the RCF Admix Variomatic foam proportioning system is used, with which wetting agent with a proportioning ratio of 0.1 % can be produced. The foam compound is injected directly into the pressure outlets, which means that the water pump remains free of foam compound and does not have to be flushed after each use. In addition, water can be discharged simultaneously from one outlet and fire fighting foam from another, and several injection points can be operated with different proportioning ratios. This specific vehicle is equipped with an RM15C water turret (1,500 l/min at 10 bar) on the bumper, which enables safe discharge of the extinguishing agent in pump and roll mode from the driver’s cab by means of a joystick, and a rapid intervention system in the pump compartment with a high-pressure nozzle. The pump and the foam proportioning system are supplied by a 3,100-liter water tank and a 100-liter foam compound tank.

The details of forest fire fighting trucks are defined by regulations and standards in many countries, although these differ greatly from one country to the next. The decisive factor in all of this, however, is always whether a tank firefighting vehicle is purchased mainly for forest firefighting or rather as a classic TLF, which is also used in the event of a forest fire. This in turn depends on the end user or organization (military, volunteer structure, etc.) responsible for wildland fire fighting in each country. The standards describe almost exclusively small, maneuverable and robust 4×4 forest fire fighting trucks that fight fires on the front line. In the event of an operation, these are supported by larger vehicles, as can be seen in the calendar picture, which ensure the supply of extinguishing agent or, if necessary and if there is sufficient accessibility, can also engage in fire fighting operations themselves.

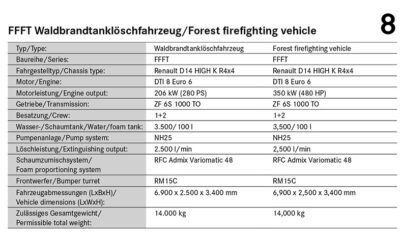

Technical data

Leave A Comment