The powerful HL3 Ex hand and helmet lamp for the HEROS Titan, HEROS H30 and HEROS H10 firefighting helmets is suitable for use in potentially explosive atmospheres in Zones 1, 2, 21 and 22 in accordance with EN 60079-0:2018 and EN 60079-11:2012. It has been developed, manufactured and tested according to current technical standards. With its modern LED technology and an LED service life of up to 100,000 hours, the HL3 Ex is a robust and reliable companion for firefighting operations. The centrally positioned lamp is one of our best-selling accessories; every second helmet is ordered with a helmet lamp.

What distinguishes the HL3 Ex from ordinary helmet lamps?

The HL3 Ex helmet and hand lamp is a critical component when it comes to illuminating the immediate surroundings in the event of an emergency, and can be mounted and removed from the HEROS Titan, HEROS H30 and HEROS H10 firefighting helmets effortlessly and without tools. The central position of the helmet lamp on the head of the firefighter underlines the focus on ergonomic requirements, to which Rosenbauer’s protective equipment attaches particular importance. In addition, the helmet lamp, with its 5 different operating modes, provides the perfect lighting for every situation. With an operating time of over 10 hours in normal mode and a maximum light output of more than 250 lumens in boost mode, it is one of the most powerful lamps in this sector.

Operating modes:

- Mode 1: Normal mode (switch-on brightness approx. 60 lm)

- Mode 2: Reading mode (reduced brightness approx. 8 lm)

- Mode 3: Turbo mode (average brightness approx. 120 lm)

- Mode 4: Boost mode (maximum brightness approx. 260 lm)

- Mode 5: Flashing mode

The HL3 Ex helmet lamp can be used with the HEROS Titan, HEROS H30 and HEROS H10 firefighting helmets.

What does Ex protection mean?

The really special feature of the HL3 Ex compared to conventional helmet lamps is the so-called Ex protection. This describes the degree of protection when operating the helmet lamp in potentially explosive atmospheres, preventing unintentional ignition of the explosive gas or dust during operation of the helmet lamp. This Rosenbauer helmet lamp is approved for Zones 1, 2, 21 and 22 in accordance with EN 60079-0:2018 and EN 60079-11:2012.

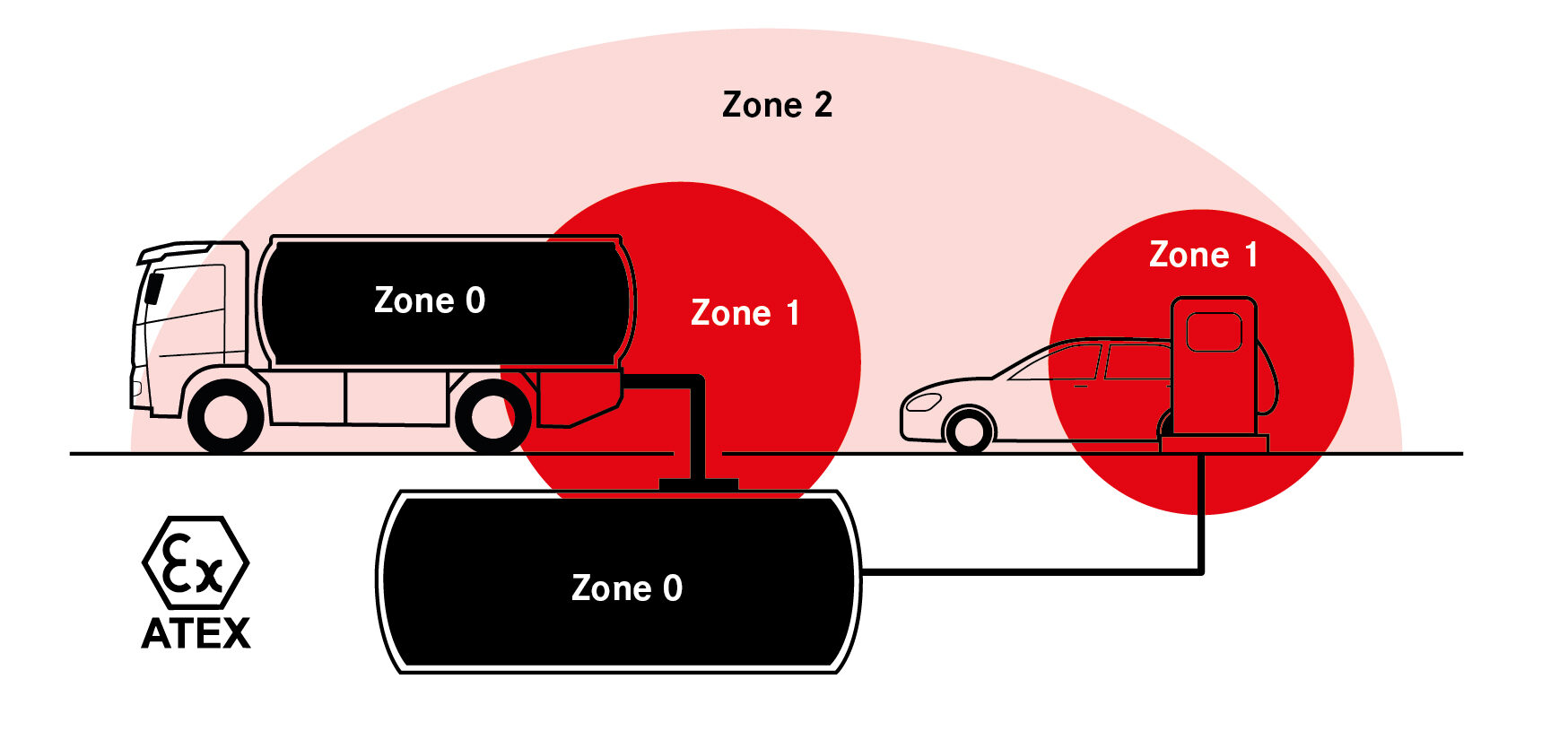

Potentially explosive atmospheres are assigned to standardized zones, which are divided into two areas:

- Areas at risk of gas explosions

- Areas at risk of dust explosions

In simple terms, the classification of zones is based on the frequency of occurrence of explosive atmospheres.

| Zone definition of potentially explosive gas atmospheres according to EN 60079-10-1 | Zone definition of potentially explosive dust atmospheres according to EN 60079-10-2 | Type of hazard |

| Zone 0 | Zone 20 | Constantly, long periods, frequently |

| Zone 1 | Zone 21 | Occasionally |

| Zone 2 | Zone 22 | Normally not, only for a short time |

The zones can clearly be described as follows:

- For flammable gases

- Zone 0: Locations inside gas-containing containers, permanent or frequent accumulation of flammable gas

- Zone 1: Areas adjacent to gas-containing containers, occasional presence of flammable gas, e.g. after opening a filler cap

- Zone 2: Areas in the vicinity of zone 1, flammable gas is normally not present in this area or only present for a short time

- For combustible dusts

- Zone 20: Locations inside dust-containing containers, permanent or frequent accumulation of combustible dust

- Zone 21: Areas adjacent to containers containing dusts, occasional presence of combustible dusts, e.g. after opening a filler cap

- Zone 22: Areas in the vicinity of Zone 1, combustible dusts are normally not present in this area or only present for a short time

The assessment of danger zones depends on many factors, and must be considered on a case-by-case basis. (As an example, for gases heavier than air, a depression in the danger zone can become Zone 1, even if it is not located immediately adjacent to the source of the release, as an accumulation of the gas can form there). The graphic below shows what a simplified ATEX zone classification could look like.

Simplified example of an ATEX zone categorization

How is the helmet lamp manufactured?

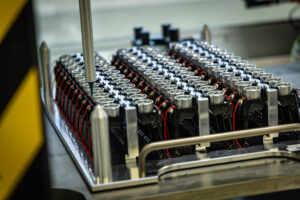

The production of helmets and hand lamps, and therefore also the added value, takes place in Austria, setting the path towards CO2 neutrality in terms of sustainability and reduced delivery distances. The helmet lamp is assembled, and the circuit board is fitted using state-of-the-art manufacturing processes in a climate-controlled environment. Quality controls along the entire production process ensure compliance with the requisite high ATEX quality standards that our customers are accustomed to.

The individual production stages in detail:

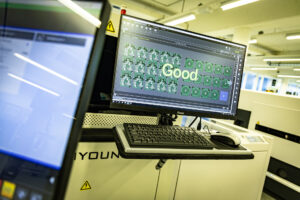

- Fully automated circuit board production using state-of-the-art machinery. Each circuit board/component/solder joint is 100% checked using a 3D measuring process.

- Subsequent programming of the circuit board including various function checks

- Fully automated encapsulation process for the circuit board including the optical unit in the helmet lamp housing (ATEX-relevant)

- Final assembly and packaging

- Assembly with precision placement machine

- Testing and inspection – AOI

- Programming, including functional test of the software

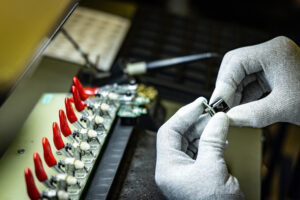

- Mounting the optical lens on the circuit board

- Soldering the battery contacts

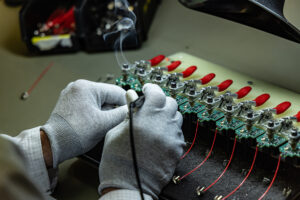

- Casting the on/off switch on the circuit board

- Automated casting of the optical unit

Conclusion

The HL3 Ex: safe to use and with optimum luminosity, an indispensable companion for every firefighter.

Leave A Comment