The RTE PX 14 power generator is a powerhouse for all applications, and demand for it is correspondingly high. With the switch from bench to line production, the company has responded to the increased demand, adapting production accordingly. And there are beneficial side effects to this, namely optimized logistics and a lower environmental impact.

Engine, generator, electronics, carrying frame, small parts and covers: It takes many work steps before all the components are installed, and a finished and tested RTE PX 14 is able to leave Rosenbauer’s main plant in Leonding. This is because there is a great deal of expertise combined with high-quality technology and electronics in the powerful power generator, which is popular with fire departments around the world thanks to its practical features.

While its predecessor, the RS 14, was still assembled by a single fitter on a bench, the assembly of the RTE PX 14 has been switched to line production. Greater efficiency and optimized logistics have not only increased productivity but can also save valuable resources.

From the empty wagon to the completed power generator

The RTE PX 14 begins its life cycle as an empty multi-level wagon. This wagon with several racks is about the size of a Euro pallet. 27 of these wagons are put on an articulated truck, which transports them directly to one of the parts suppliers. There, the wagons are loaded with all the sheet metal parts, before returning to our logistics center. The full wagons are unloaded, and the next batch of empty wagons is sent off on its journey.

Much less packaging material

In the logistics center, they are fitted with other components such as the battery, control panel, wiring set, fuel tank and exhaust before moving on to production. The major advantage of this approach is that the supplier does not have to pack each part individually and unpack it again at Rosenbauer. This means a lot of waste is avoided before it even appears. Only the larger components such as the engine and generator are delivered directly to production, with the usual small parts – like screws and seals – also being made available there.

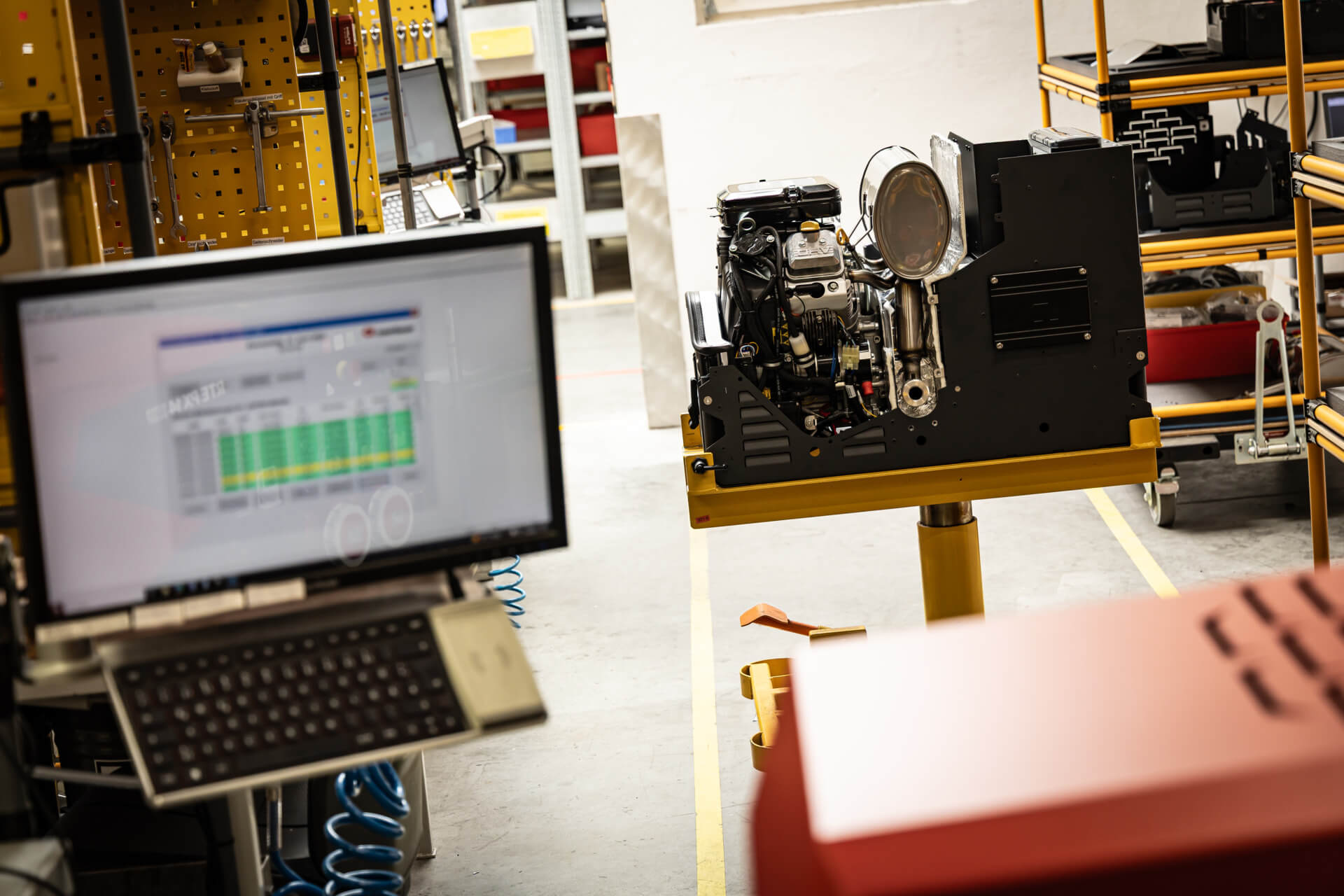

Once at the production line, assembly begins: at the first station, the carrying frame is assembled, the wiring set installed, and the tank attached. The engine and generator are then connected and placed in the carrying frame before the journey of the multi-level and auxiliary assembly wagon continues to the next station.

Equipped according to customer’s needs

Depending on the configuration of the RTE PX 14 ordered, the components selected by the customer are then installed: the sockets, operating display, and associated internal components are fitted by the fitters. This is followed by the various covers, lettering and stickers, before the software is finally implemented.

After this comes a rigorous test on the internal test bench: once the new RTE PX 14 has successfully passed all the tests, the generator is prepared for dispatch.

Depending on the order situation, two or three fitters work on the assembly line, producing between two and four power generators per day. The exact number depends not only on the order situation, but also on the individual requirements of the customer. The highly trained craftsmen and women benefit just as much as the customers from the optimized processes: the switch from bench to line production has made the workflow clearer and even more practical. And thanks to the enormous number of versions in which the RTE PX 14 is available, production at the well-equipped workstations remains incredibly versatile.

Leave A Comment